Our group also adopts a new state of the art technology.

- Interlock Pile

- Wet Drilling

Interlock Pile

Interlock Pile is an alternative for the sheet pile. It is an interlocking system designed in such a way that it can be rigid enough to confront water current. It can be used as permanent water retention system for foundation construction in coastal areas. Drilling of Interlock Pile is done using down-to-hole technique with air control bits for low disturbance and safe drilling. There is no chance of over drilling or air escaping due to these special drill bits. Interlocking is carried out using new system called connector elements which are spirally or longitudinally welded steel pipe piles.

Common Use:

- Dock construction and quay walls

- Flood control and support walls

- Vertically sealed enclosure walls (Cut-off walls)

- Preventing water pollution.

- As foundation.

- Downstream of hydropower tunnel to prevent the slope against erosion due to impact of wave

- Water barrier structure.

Advantages:

- Prevention of Soil Settlement.

- No disturbance to the works above.

- Water tightening.

- Resistance form the wave impact.

- Prevent Leachate flow.

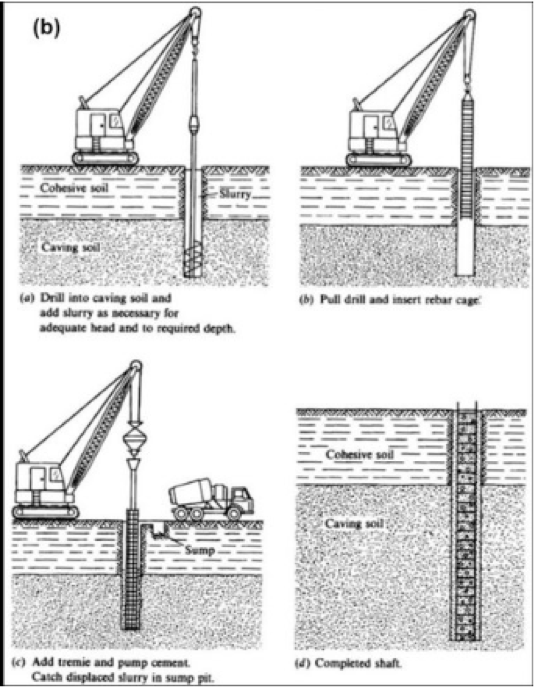

Wet rotary drilling

The wet rotary method of drilling uses a drill bit that is mounted on the end of a drill rod and is

advanced by the rapid rotation of the bit. The cuttings are removed by pumping drilling fluid

(water or water mixed with bentonite or other fluid enhancers) down through the drill rods and bit

and up the annulus, between the borehole and the drill rods. The drilling fluid also serves to cool

the drill bit and stabilize the borehole walls.

Wet rotary drilling methods have a number of benefits. It is a very fast and efficient means of

drilling efficient drill-rigs can produce several hundred feet of hole per day. Wet rotary is adaptable

to a wide range of geologic conditions. However, exceptionally large, poorly stabilized boulder

conditions are unsuitable for wet rotary drilling. Sediment sampling is broadly supported and thin

wall and split barrel sampling is available.

Advantage:

- High quality undisturbed sampling (hydraulic or mechanical fixed piston thin walled tube samples)

- High quality SPT testing, with a calibrated SPT hammer (SPT energy testing)

- High quality in-situ testing (EVST, PMT, DMT, other)

- Representative samples at discrete elevations

- Performed on its own, or through Air Rotary or Sonic Drilling or Auger Drilling cased holes

- On or off-shore applications

Common use:

- High quality geotechnical site investigation requiring detailed laboratory and in-situ testing.