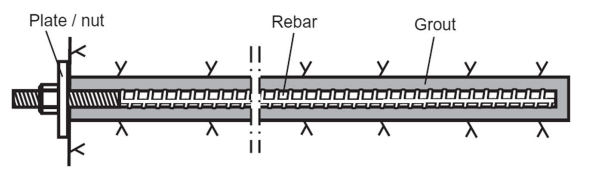

A fully threaded anchor has threads that run the whole length of the anchor. Threading action provides gripping across the full length of the anchor, which in turn provides a better bond between grout body and anchor. Fully threaded anchors are the grout/ mortar embedded reinforced steel members used for slope stabilizations, rock strengthening, and reinforcement in underground tunnels and mining.

The design of a fully threaded anchor system depends on the rock/ soil parameters and geometry of anchor arrangements. Based on the stability of ground conditions, the anchor locations, inclination of the slope, angle of installation, spacing pattern, and length is designed and installed.

Source: Kabwe, E. Numerical Analysis of a Rock Bolt Load Indicator Washer Neglecting the Stress Relaxation Effect. Mining, Metallurgy & Exploration 37, 691–700 (2020)

Commonly, the fully threaded anchors are a minimum diameter of 25mm with a yield capacity of 200 kN (minimum) of steel grade of Fe 415 used for the temporary tunnel supporting system/ slope stabilization requirements. These are the lower limit of specifications, but the anchor specifications and mechanical properties may be changed as per the requirement of slope/ rock actual conditions. Max. Diameter can be up to 75 mm with a yield capacity of 2209 kN.

Installation procedure:

- Boreholes drilling

- Manual insertion of the fully threaded anchorinto the borehole

- Fill the grout into the borehole.

- Proper curing is required.

- Fixation of the anchor plate.

- Tensioning of anchor bolts-head using a tightening of the nut.

Applications:

- Mainly use for temporary supporting in tunnels.

- Anchorages of rock and rock stability

- Ground support and slope stability.