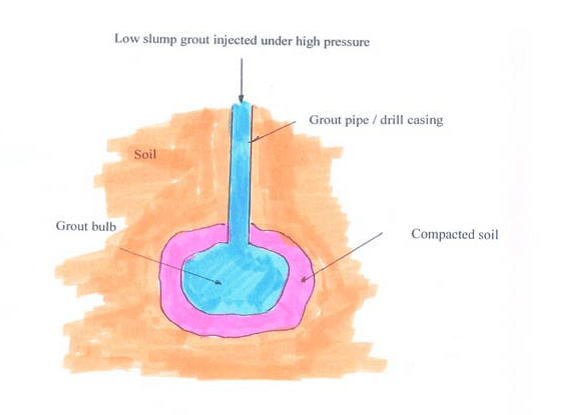

Compaction grouting involves the injection of a low slump, mortar grout to densify loose, granular soils and stabilise subsurface voids or sinkholes. The grout mix must have specific characteristics; a very low mobility (low slump) mixture that is ‘pumpable’ but upon installation, exhibits an internal friction enabling it to remain intact and displace the surrounding soil without fracturing it Compaction grout improves ground conditions by displacement of soil particles.

A high viscosity (low mobility) aggregate grout is pumped into the ground in stages to displace and densify the surrounding soils. By sequencing the grout injections from primary to secondary and tertiary locations this densification process can be performed to achieve the required improvement.

Common Uses

Suitable for rubble fills, poorly placed fills, loosened or collapsible soils, soluble rocks and liquefiable soils

- Often selected for treatment beneath existing structures because the columns do not require structural connection to the foundations

- Decrease or correct settlement

- Increase bearing capacity

- Stabilise sinkholes or reduce sinkhole potential

- Pinpoint treatment and Speed of Installation

- Non Hazardous and No waste disposal

- Can be performed in very restricted access

- No need to connect to existing foundations

- Economic alternative to removal & replacement or piling

- Volume and pressure control options