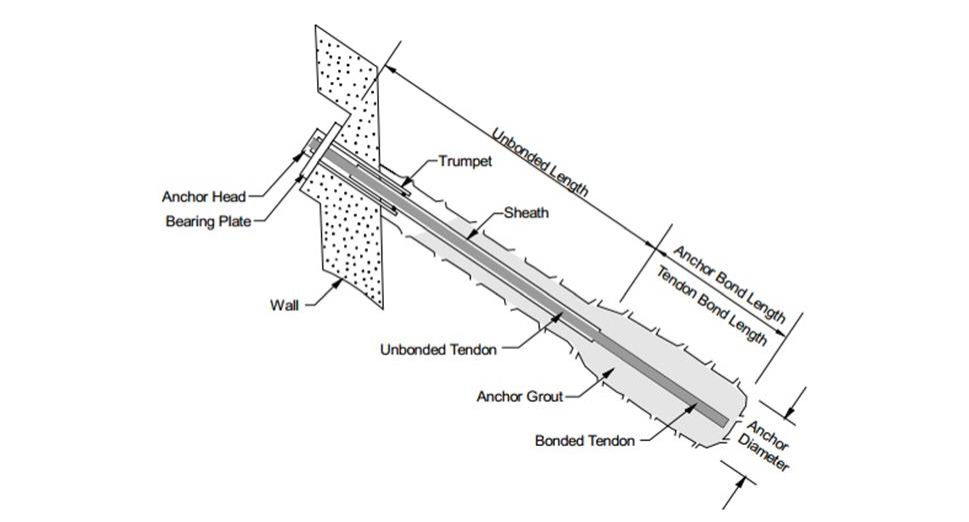

Ground Anchors are the structural members that are installed deep into the rock mass with their main applicability to transfer the applied tension load deep into ground/rock mass. Sometimes, also referred to as tieback anchors. The main component of the ground tieback anchor is shown in figure 1. The anchorage is the combined system of anchor head, bearing plate, and cladding wall that enables the transfer of the prestressing applied tension force from the prestressing steel (bars or strands) to the ground surface.

Figure 1. Components of a ground anchor.

Another ground anchor component is the unbonded length, which is free to elongate and transfer the resisting force from the bond length to the front cladding wall. Based on stressing, there are active and passive anchors. Active anchors are prestressed in which tensile force is transferred through the free length. Passive anchors, in which the tensile force developed after the ground deformation. A bond breaker is a smooth plastic sleeve that is placed over the tendon in the unbonded length to prevent the prestressing steel from bonding to the surrounding grout. The bond breaker’s main purpose in the prestressing steel is the unbonded length is free to elongate if it during testing, stressing, and after lock-off. The anchor’s main component is tendon bond length bonded to the grout and capable of transmitting the applied tensile load into the ground. The anchor bond length should be located behind the critical failure surface ground.

Tendon is the main portion on the assembling of the ground anchor. The tendon includes the prestressing steel element (strands or bars), corrosion protection, sheaths (also referred to as sheathings), centralizers, and spacers. The sheath is a smooth or corrugated pipe or tube that protects the prestressing steel in the unbonded length from corrosion. Centralizers position the tendon in the drill hole such that the specified minimum grout cover is achieved around the tendon. For multiple element tendons, spacers are used to separate the strands or bars of the tendons so that each element is adequately bonded to the anchor grout. The grout is of various mix proportions. Minimum M25 grade should be used that provides load transfer from the tendon to the ground and provides corrosion protection for the tendon.

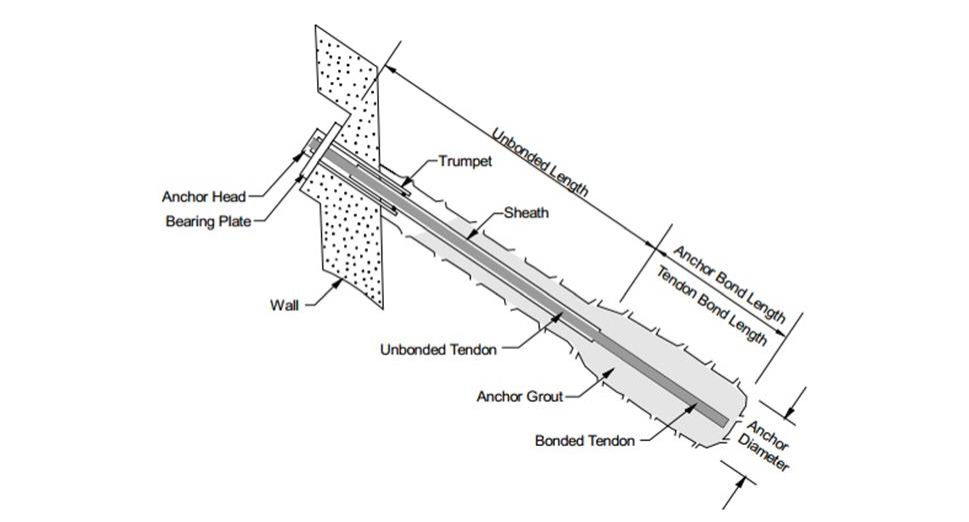

Types of Ground Anchors

- Straight shaft gravity-grouted anchors

This type anchors mostly suitable in rock strata and very stiff to hard cohesive soil deposits using either rotary drilling or hollow-stem auger methods. Tremie (gravity displacement) methods are used for grouting the anchor in a straight shaft borehole.

- Straight shaft pressure-grouted anchors

This type of anchor is most suitable for weak rock strata and coarse granular soils. This anchor type is also used in fine-grained cohesionless soils. In that grout is injected into the bond zone under pressures greater than 0.35 MPa.

- Post-grouted anchors

Post-grouted anchors use delayed multiple grout injections to enlarge the grout body of straight shafted gravity grouted anchors.

- Under reamed anchors

Under reamed anchors consist of tremie grouted boreholes that include a series of enlargement underarms. This type of anchor may be used in a firm to hard cohesive deposits.

Figure 2: Different types of ground anchors

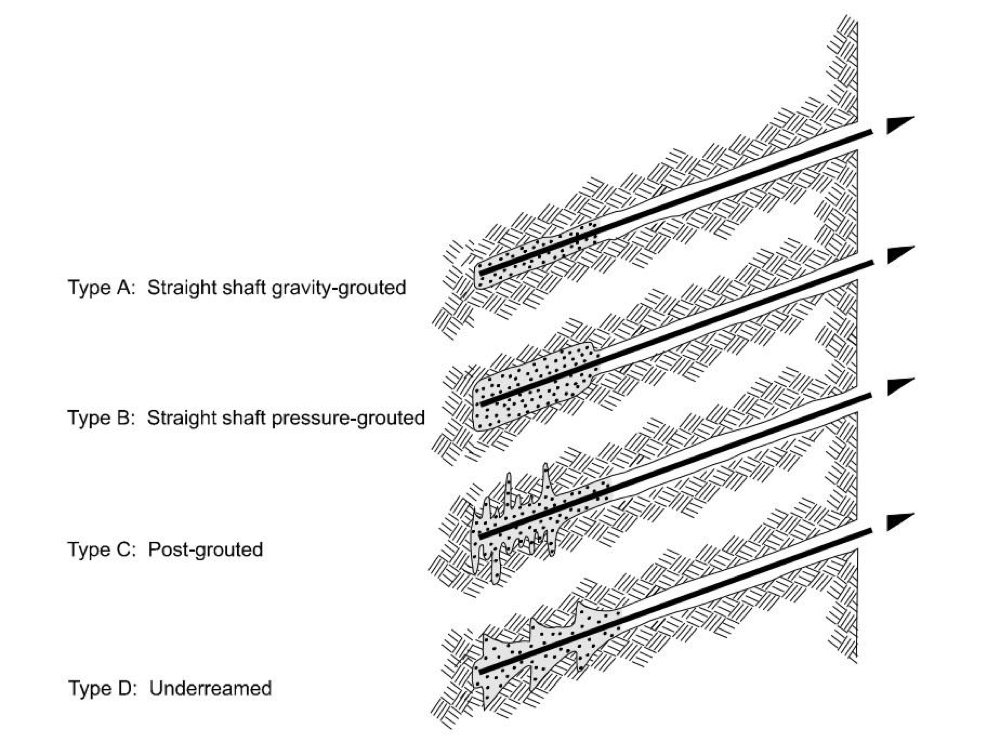

Applications

- Use of Anchors to Improve Slope Stability

- Applications for Dam Strengthening and Restoration

- Anchorages for Concentrated Forces

- Anchorages to Secure Caverns

- Anchorages for Tunnels

- Anchorages for Underpinning

- Anchorages for Deep Excavations

- Anchorages for Long Excavations

- Anchoring of Foundation Structures

- Waterfront Installations and Offshore Structures

Figure 3: Applications of ground anchors

Anchor Load Testing

As compared to other structural members, there is a unique aspect of anchors, is that every anchor is load tested to verify its load capacity and load-deformation behavior before being put into service. The acceptance or rejection of ground anchors is determined based on the results of:

1- Performance tests

Performance tests involve incremental loading and unloading of a tendon anchor. The performance test is used to verify anchor capacity, establish load-deformation behavior, identify causes of anchor movement, and to verify that the actual unbonded length is equal to or greater than that assumed in the anchor design.

2- Proof tests

The proof test involves a single cycle load and a load hold at the test load. The magnitude of the applied load is measured using the jack pressure gauge.

3- Extended creep tests

An extended creep test is a long duration test (e.g., approximately 8 hours) that is used to evaluate creep deformations of anchors.

The acceptance criteria are based on allowable creep and elastic movements of the anchor during load testing. The results of these anchor tests are compared to specified acceptance criteria to evaluate whether the ground anchor can be put into service.

Advantages

- Practical alternative propping and Execute excavations neatly to create large construction plans without using props in order to make a mechanized excavation. Less Excavation is required.

- Eliminates backfill behind the wall and also eliminates the deep foundation construction

- Reduces the concrete quantity for the front wall; typically, 300 mm thickness is required.

- Method of quick construction and reduced cost of construction.

- Anchors combine with cladding walls to re-distribute the internal forces of wall structure, so this can reduce the size, depth of steel bars in the cladding wall, or retaining walls.

Disadvantages

- It is difficult to apply anchors in very weak soil strata and to implement anchors with greater depths due to the less pullout capacity.

- Continuous groundwater flow and constant seepage sometimes wash away the grout. For this situation, special admixtures and other techniques are incorporated.