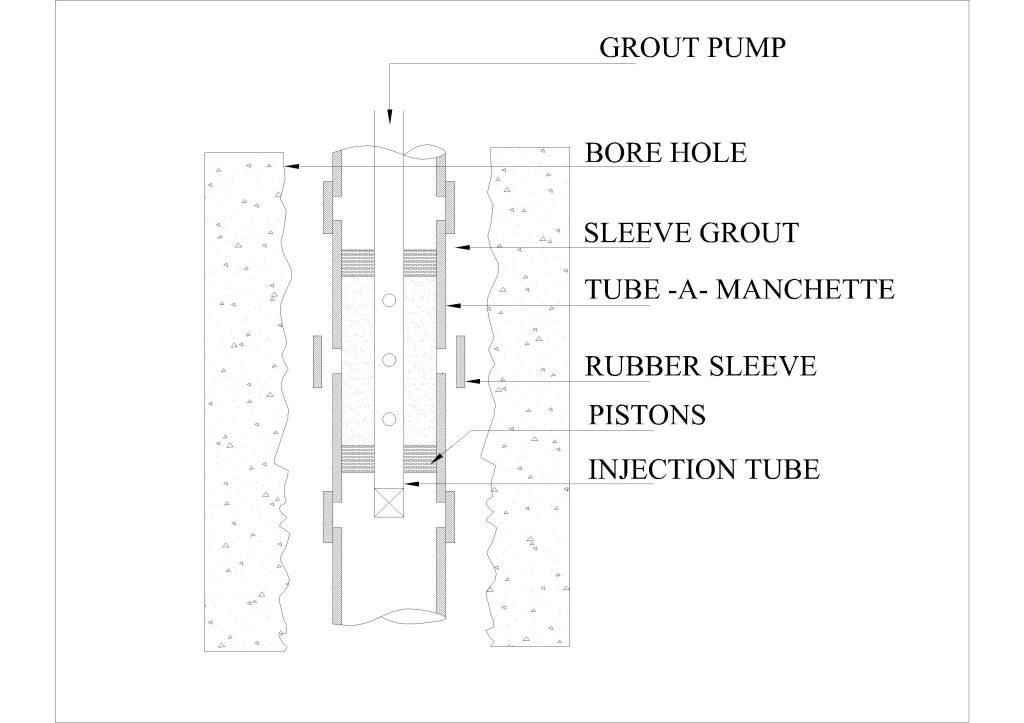

Tube a Manchette (TAM) grouting method involves the use of perforated pipe along with a special sleeve grout. These pipes/tubes are then inserted into the hole for grouting with short sections of rubber sleeve (Manchette) on the outer part of the pipe that acts as a one-way valve.

Double packer is used to pump the grout into manchette tube until the packer is halfway past the set of the holes drilled into the tubes. Grout is pumped into the hole between confining packers by applying pressure. Pressure pushes the grout past the small rubber sleeves to cover perforation, rupture the sleeve grout and enter the soil.

Common uses

- Tunnel excavations

- Cofferdams

- Cohesion-less granular soils

Advantages

- It is possible to inject grout accurately at required locations.

- The manchettes, which act as one-way valves, prevent the injected grout from flowing back into the grout pipe under high grouting pressure. Thus perfect grouting effect is attained.

- It enables re-grouting, which permits the use of grouts with decreasing viscosities. This permits better penetration of the fine voids after the big ones have been closed. More permeable soil layers can be sealed first regardless of the order of injection level, which prevents loss of high-cost, low-viscosity grouts.

- The grouting operations are carried out completely independent of drilling which is very convenient for job execution.